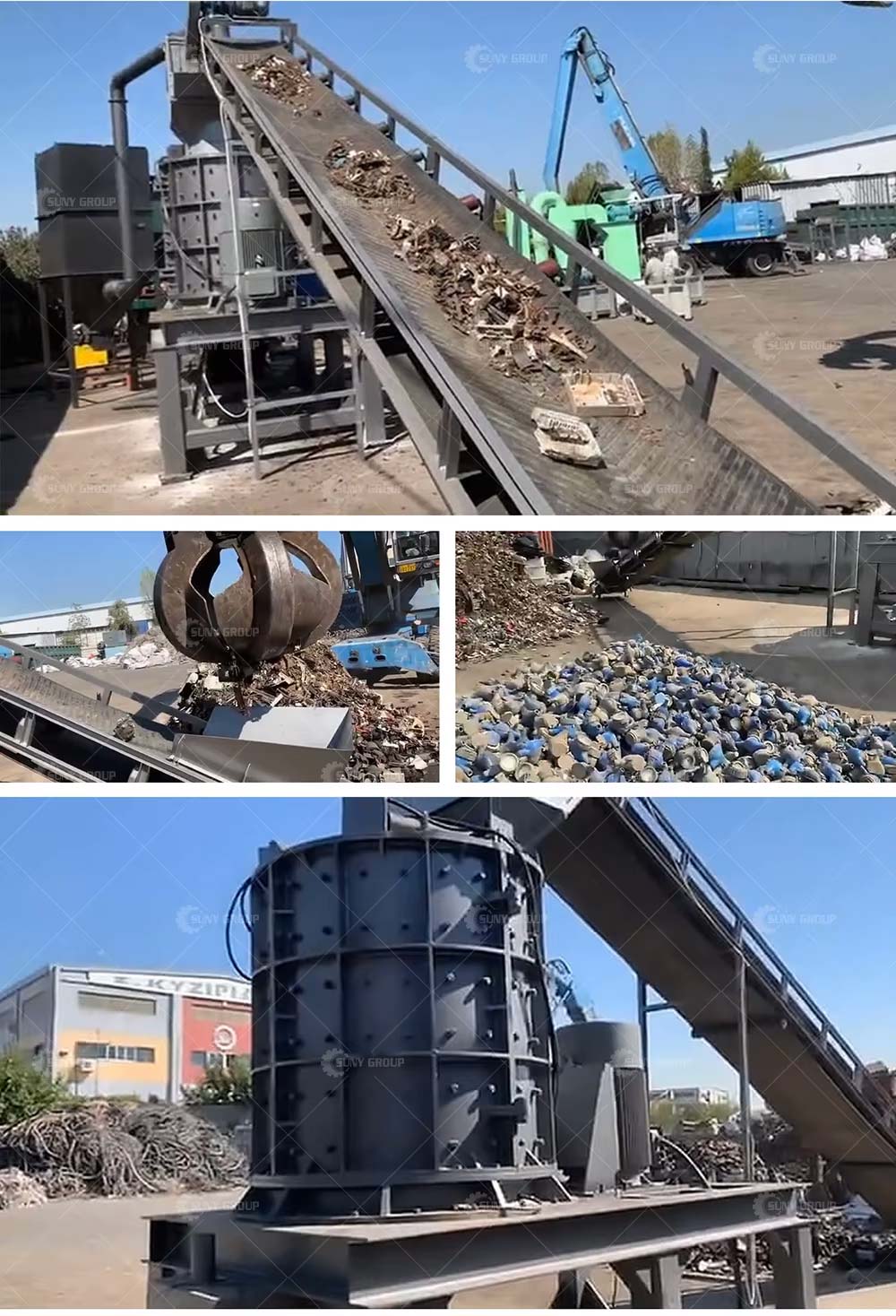

Vertical metal crusher

The vertical metal crusher mainly uses the upper hammer structure to break materials by rotating at high speed. In the process of material automatic falling, the material is finely crushed and rolled by the gap between the lower hob and the crushing cavity. Meet the discharge requirements. Vertical crusher is characterized by its structure, high crushing speed, high efficiency and easy maintenance.

The main application materials are: scrap metal, aluminum profile, motor stator, rotor and other waste mixed metal materials.

Conveyor, vibrating screen, magnetic separation, dust removal and other equipment can be configured. Magnetic separation can directly separate iron and other metals, and dust removal equipment can directly achieve pollution-free emission. The crushed materials are clean and bright, which can directly meet the requirements of feeding into the furnace.

- Easy to Install & Operate

- Long Life & Low Cost of Maintenance

- Certified with CE/SGS/IOS/GOST, etc.

Information

- Capacity:800-3000kg/h

- Raw Materials:All kinds of scrap metal

- Final Products:Small pieces of granular material

Features

-

high speed

The rotating speed can reach 672 revolutions per minute,and the crushing equipment with the same power has higher discharging eficiency.

-

pollution-free

Equipment is equipped with inlet and outlet belts,and the outlet is equipped with dust removal equipment,which greatly reduces dust pollution during crushing.

-

durable

The equipment is equipped with 72 liners made of high manganese steel,which have good wear resistance,toughness and durability.it is suitable for the initial breaking of materials with lage particle size.

-

easy to maintain

The design of double-door makes the maintenance of the equipment simpler.the unique design of the chinese market,the opening angle of theequipment is 180 after the hydraulics on both sides are opened.

-

unique structure

The upper side of the metal crusher is a high-speed rotating hammer head,and the lower part is a self-rotating and revolving hob,which can quickle crush materials.

Parameters

| Model | Capacity(kg/h) | Power(KW) | Spindle speed(rpm) | Rotating Diameter(mm) | Number of hammes | Unit weight of hammer head | Number of hobs | Unit weight of hob | kicking device | Power of hydraulic station | Hammer head material | Equipment weight(tons) | Equipment size(mm) |

| ZY1000 | 800-1000 | 75*2 | 650 | 1000 | 2pcs | 20kg | 36pcs | 40kg | Active type | 2.2kw | High manganese alloy steel | 9 | 1200*1200*3000 |

| ZY1200 | 1500-2000 | 90*2 | 650 | 1500 | 4pcs | 25kg | 36pcs | 40kg | Active type | 2.2kw | High manganese alloy steel | 12 | 1500*1500*3200 |

| ZY1500 | 2000-3000 | 132*2 | 672 | 1500 | 2pcs | 30kg | 36pcs | 42kg | Active type | 2.2kw | High manganese alloy steel | 18 | 1800*1800*3500 |

Customer work site

INQUIRY