- cost of hydraulic briquetting machine for waste recycling

- Energy-Efficient Balers

- high pressure briquette press for copper slag

- metal powder briquetting machine for smelting furnaces

- briquette machine with automatic feeding system

- industrial hydraulic briquetting press for steel swarf

- Double Shaft Shredder: Structure, Materials, Working Process, and Output

- compact briquette press for aluminum scrap workshop

aluminum copper waste radiatorcutting separating machine

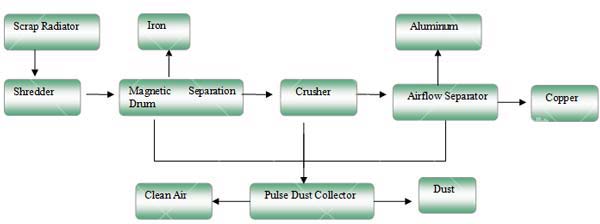

Aluminum copper waste radiatorcutting separating machine is a professional equipment for processing waste radiators, which can achieve accurate separation of metal materials. The equipment is driven by a hydraulic system and equipped with high-hardness alloy cutters, which can quickly cut the radiator shell. During the separation process, the multi-stage screening system automatically classifies the aluminum fins, copper tubes and iron parts, and the separation purity can reach more than 98%.

aluminum copper waste radiatorcutting separating machine

The equipment workflow includes four main links: feeding, cutting, crushing and sorting. First, the radiator enters the cutting area via a conveyor belt, and the hydraulic cutter decomposes it; then it enters the crushing link to crush the material to a suitable particle size; finally, the vibrating screen and airflow sorting are used to achieve efficient separation of aluminum, copper and iron. The whole process adopts a closed design and is equipped with a dust removal device to effectively control dust pollution.

This equipment has significant significance for environmental protection. Through metal recovery, the environmental damage caused by mineral mining is reduced; the separated pure metal can be directly used for reproduction to reduce energy consumption; the closed operation and dust removal system reduce dust emissions. According to statistics, processing one ton of waste radiators can reduce carbon emissions by about 5 tons and save 8 tons of mineral resources.

The promotion and application of aluminum-copper waste radiator cutting and separation machines not only improves resource utilization efficiency, but also provides reliable technical support for the development of circular economy. It is an important environmental protection equipment for achieving sustainable development.

INQUIRY